Overland Conveyor Modernization to Gearless Drives

ROXON has delivered long Overland Conveyors since 1980’s to all major companies in the Nordic countries. One example is a 3 km long overland conveyor delivered in 1988 which is still in operation in Sweden. ROXON changed the belt to the same conveyor for the first time in 2022.

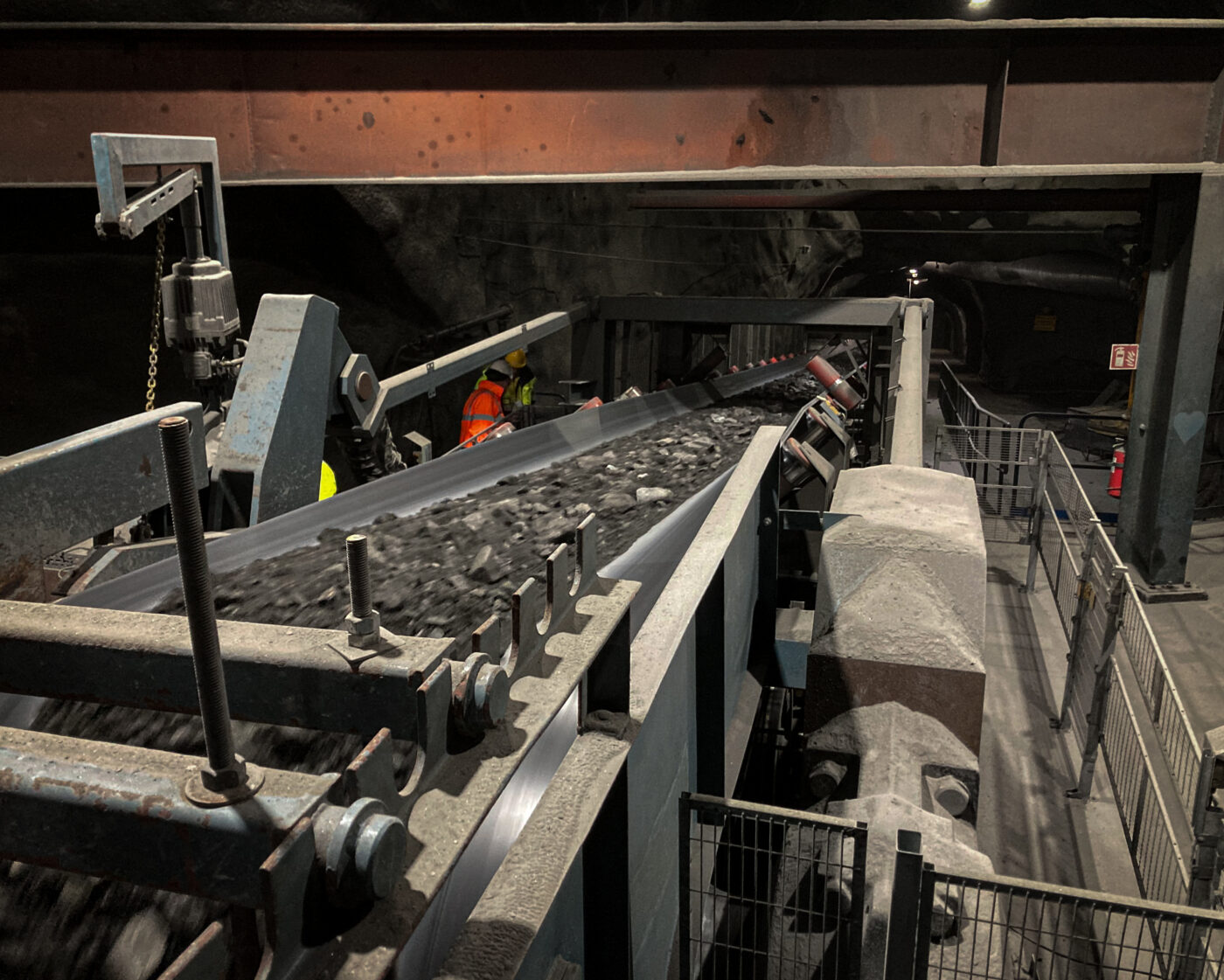

The history and track record of ROXON in deliveries of overlands and high-capacity conveyors is long. LKAB Malmberget, ROXON’s customer since 1970,’s purchased a 1,7 km long underground conveyor which was delivered in 1999. LKAB has recently decided to change the original drives to direct drives, more precisely permanent magnet motors. At the same time, the capacity of conveyor is increased from 3000 tph to 3600 tph.

LKAB Project Manager Pär Sundqvist explains the background of the modernization:

“The upgrade of the drivetrain for this conveyor is done primary out of capacity reasons but also from a perspective of energy efficiency. By doing this upgrade we expect a possibility to rise the utilization of the whole production line of the mine somewhere around 2-5%.”

The change from traditional geared drives to gearless drives is creating significant changes to conveyor dynamics since the inertia of drive station is significantly reduced. Therefore, LKAB ordered expert services from ROXON to execute the dynamic analysis of the conveyor. In a dynamic analysis starting, stopping, emergency stop, and all other possible scenarios are simulated to find out transient tensions during the specific event.

Dynamic analysis answers the following questions:

- How the braking shall be done to minimize the maximum transient belt force but holding sufficient minimum tension considering all cases?

- What will be the counterweight movements in all situations?

- Is there a need for a capstan brake?

- How to execute an emergency stop without risking safety or harming the conveyor?

ROXON optimizes all overland conveyors using dynamic analysis tools (>1km in length, very high capacity or exceptional geometry). These conveyors are complex machines and the results from a dynamic analysis define the conveyor function in detail to ensure high availability and safe operation for decades.

Teemu Lahti, Product Manager for belt conveyors was responsible for the dynamic analysis and has executed many projects in co-operation with LKAB:

“It was a privilege to be part of this project and help LKAB who we have long history together. Obviously the calculation and conveyor design has developed a lot in the last 25 years but still it’s great to see that the original design has offered great reliability and safe operation for the customer. The modernization project was started by reviewing all original data and then evaluating proposals from LKAB how the modernization was planned and which components preliminarily selected. Together we found out the suitable technical solution and LKAB can proceed with the execution.”

ROXON is also delivering a new drive pulley and refurbishes the old one as spare part for LKAB. ROXON fabricates and refurbishes the pulleys in Haparanda, close to our major customers in northern Sweden.

When your company is looking for an expert of Overland Conveyor solutions, you can trust ROXON who provides the full range of services from basic design to deliveries and even modernizations of existing equipment.

Read more about our services or give us a call!